Vincent

Technical Sections: -Serial

Numbers/Production- Photo Gallery of

Models - Brakes

- Engine

Overhaul - Vincent

Engines - Wheels/Fenders

- Instruments -

Transmission -

Clutch - Magneto - Tank/Seat - Suspension

- Tools - Norvin -

Electrics-

Carburetors - Misc - Links -Vincent

Parts/Services Suppliers - Polishing/Cleaning

- Shipping Vincents-Electric

Starter - Paint/Transfers

Vincent

Motorcycle Electrics:

Alton generator testing - Feb 2015 from K17 So cal - S. O. SEZ by Dave

Marshall - I

looked into my charging problem on my Comet this month. I

contacted the maker, Alton, and they gave

me the following instructions on checking the Alton for output:

Do

not forget to check for ground/earthing issues.

Then please do the following basic controls using a multimeter (if

not

already done):

Two

static tests (engine off):

[1-1] Test for continuity

between the 2 wires from the AC generator.

There should be CONTINUITY between those wires.

[1-2] Test for continuity

between one (or the other) wire from the AC generator and the

Alton body. There should be NO continuity.

Two

dynamic tests (engine running):

[2-1] Disconnect the AC

generator from the regulator. Start

engine. Check AC voltage between the 2

wires from the AC generator. This voltage

should reach 20-22 volts AC as soon as you rev up engine (let's

say at a high

idling rpm).

[2-2] Connect the regulator to

the AC generator with everything as it should be. Start

engine.

Check DC voltage between the 2 terminals of battery. This

voltage should reach 13 volts DC as soon

as you rev up engine (let's say at a high idling rpm).

|

Vincent Motorcycle Free Classifieds

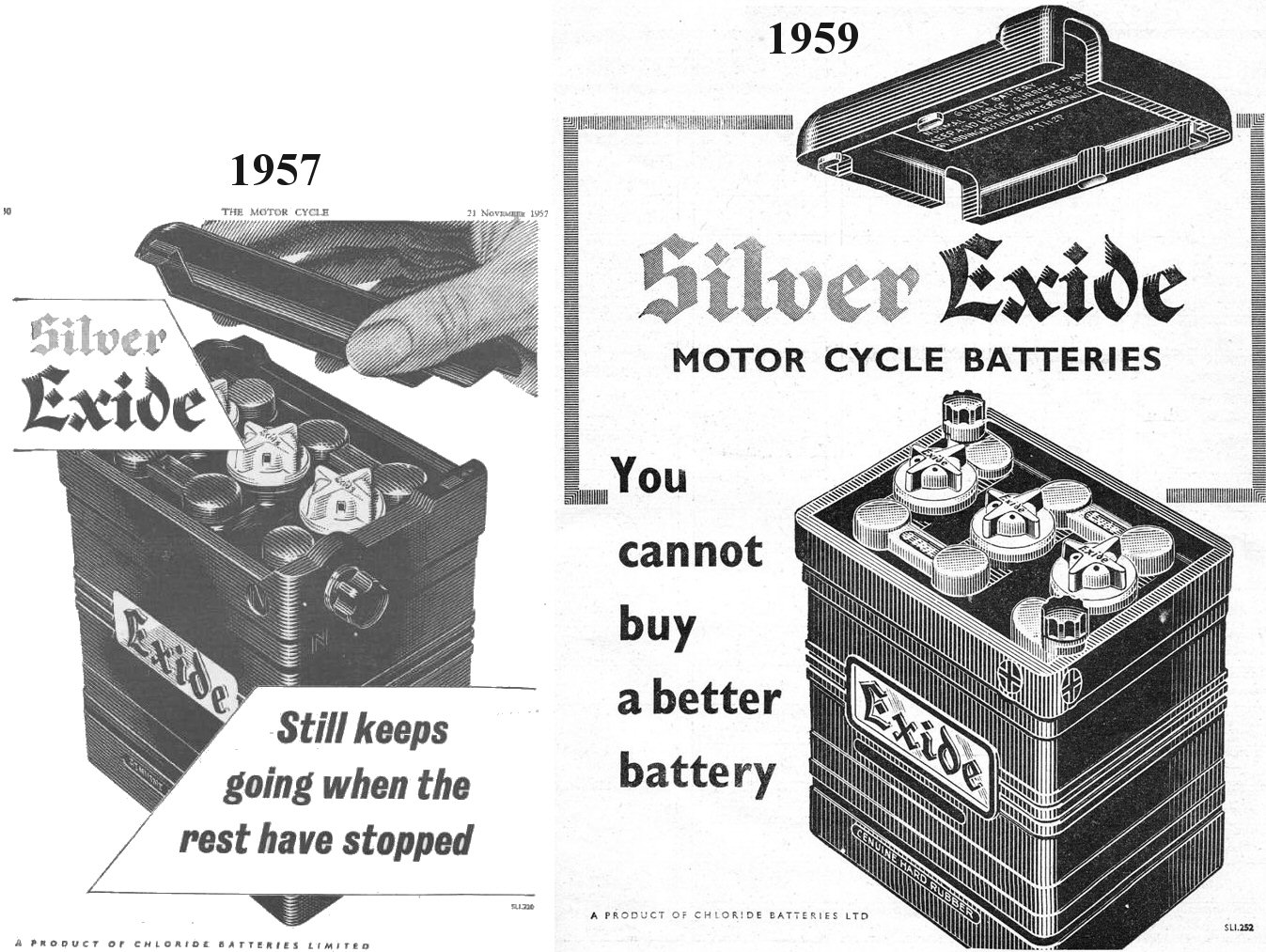

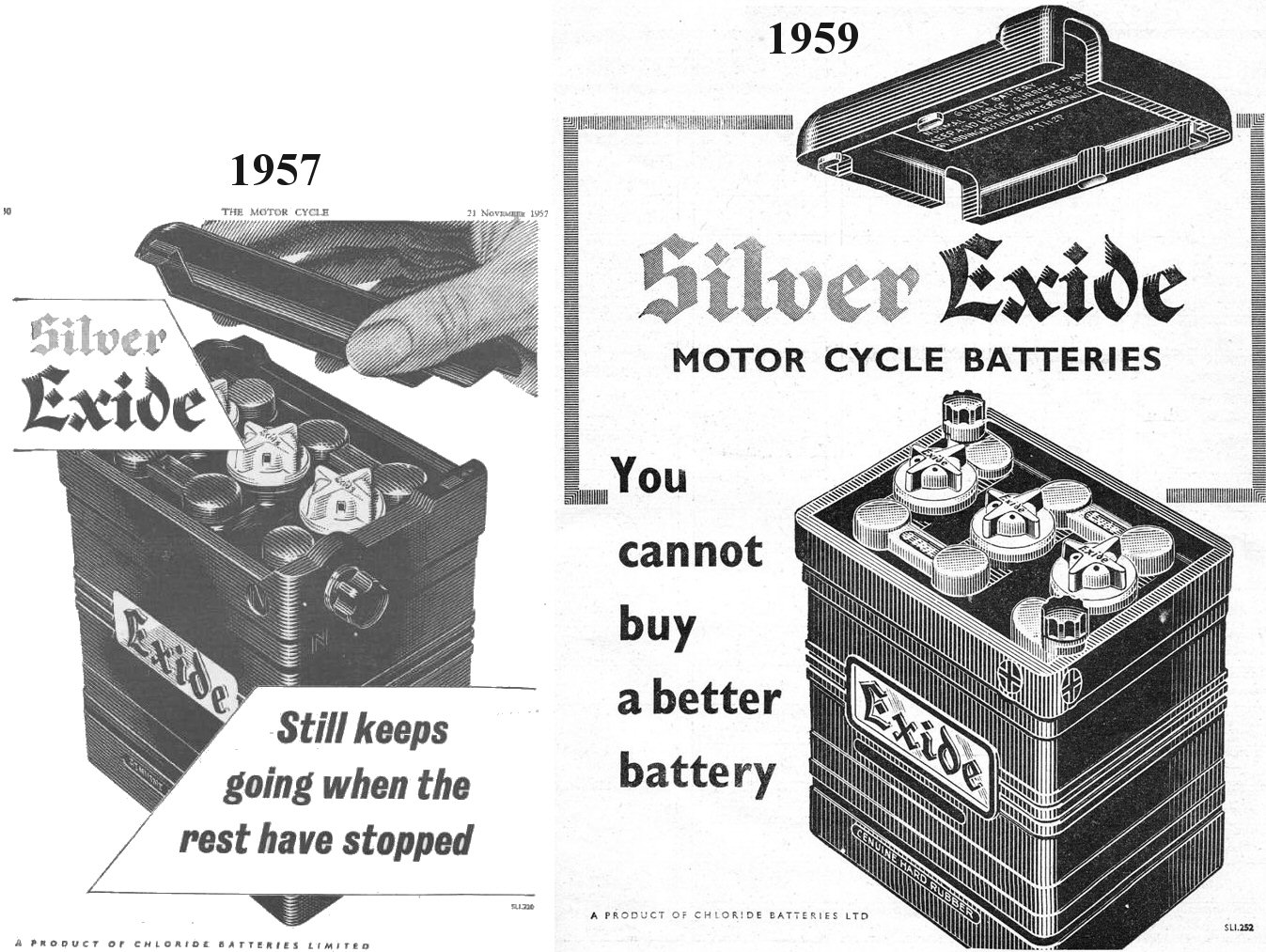

1957 and

1959 Chloride Batteries LTD - Exide battery ads

I have always wondered why the empty battery case

supplied by restoration suppliers did not seem to match

the 1947-1955 era period Vincent photos. After searching

thru 1950's era Exide motorcycle battery ads it looks

like the case design was changed in 1958 or 1959.

So now we know this empty Exide case we purchase to look

like a period battery is indeed an Exide motorcycle

battery design, simply late 1950's. If anyone has

further info please dont hesitate to contact me. I know

the earlier Exide had a variety of Bakelite post knobs,

some hex nut shaped, some large round knurled, some as

shown.

It would be nice to have some period documentation on

the colors used on the Exide battery case logo

|

The first (upper) diagram shows the insertion of a Podtronics

rectifier/regulator and an 12 volt Alton generator.

It is a bit more detailed than the diagram below, showing all

the connectors, wire colors and additional ground points.

This diagram shows a redundant - closed loop ground wiring

system. This is intended to reduce dependency on the frame for

ground purposes in the charging circuit.

The second (lower) diagram is as the bike was built using the

12 volt Alton generator and an Alton supplied

rectifier/regulator. It is a bare bones diagram.

I installed a key switch to correct the small electrical

bleed off problem with leaving the battery connected for longer

periods of time.

Within 2 years, the Alton supplied rectifier/regulator

failed, and Paul Hamon recommended using a replacement. I

selected a Podtronics unit as installed in the upper diagram

(Marc Michel TT Restorations)

Discussion of modern Voltage

Regulators:

I installed the Alton unit and I find there is a 23mA bleed to

ground through the voltage regulator green ground lead. The

Vincent 12v battery was running down when simply sitting and the

fault traced to this. What is my problem? Craig

Comontofski 11/7/2011

On the wiring diagram ("magneto" type) we suggest to add a switch to

avoid a small leak current passing through the small black wire of

rectifying regulator when the bike is at rest. This is

approximately 20 milliamps. Not very high but enough to

drain a battery in a couple of days (depending on the battery

range). So add this switch if you want to avoid this

problem. Another solution is to remove the fuse as soon as

your bike is at rest for more than a couple of days. Or

alternatively to use a home battery charger for long

rests. This inconvenience comes from the source

of rectifying-regulators. They actually come from small

capacity Japanese motorcycles on which the ignition key

switches the small black wire of rectifying-regulator (as

indicated on the other diagram). In this case no leaking

current because the battery is disconnected from the

rectifying-regulator when the bike is at rest (ignition off).

If you start the bike without switching "on" and run the generator

with "open" circuit, it is not so good for both generator

and rectifying-regulator if you insist for all trip but it

won't destroy them for just a couple of minutes running this

way. By the way if you do so you surely can hear the generator

"rumbling" and of course the needle of ammeter won't move at

all. Paul Hamon 11/8/2011

Voltage regulators for DC generators have a requirement to isolate

the battery from the generator's armature when the armature is not

rotating. Failure to do so would put a load of around 1/2 Ohm (the

resistance of the armature winding) on the battery. Mechanical

regulators use a relay. Leakage of relays is so low measuring it

would be counting single electrons. Solid state regulators

typically use a diode. All diodes have a leakage current

specification. The leakage can be measured without substantial

heroics which is to say it is in the milliampere to microampere

range. Solid state regulators for alternators use Zenor diodes to

turn thyristors (SCRs) on. SCRs are just three of four (depending

on how you like to count them) diodes in a fancy configuration.

But we are back to diodes, things that leak. The diode can be

specified to minimize leakage but at the price of compromising

another specification. The design of a regulator (and just about

anything else more complicated than a paper clip) is an exercise

in compromise. There is no Utopia. Sorry, limitations of available

technology. Doug Wood 11/9/2011

Series "D" Vincent Distributor:

40455A dist service 40455/S clockwise turn 16-18 degrees DKX2A

Weights assy= 415729 ,

contact breaker complete = 400164

points = 400415 ,

cond = 400308 ,

cap = 400136 ,

springs = 421457/S

Jim Wilson 11/10/2011

NGK B6ES spark plug equivalents: NGK 7432,

Accel 143, AC Delco 43XL, Autolite 2616, Beck Arnley

176-5002, Bosch W8CC, Champion N5C, Champion 120, Denso

W20ES-U, Denso 3051, GM 5613104, Mighty M4G3, Motorcraft

AG3CX, Prestolite 14G3, Splitfire SF405F. Bill

Babcock 8/30/10

U.S. spec Miller headlight shell on that

machine which originally took a GE 3044 sealed beam

headlight. Peter Guldan 8/17/10

For the best 6 volt battery at the best price

try the toy section at wal-mart. The 6volt battery they sell

to power the vehicles the kids ride in is actually a good battery

and the most inexpensive I've encountered, besides being the

right size for the dummy battery box. Bob Bonato

8/17/10

PODtronics regulator:

- RED wire of the regulator to the

ammeter

- BLACK wire of the regulator to earth

- YELLOW wire of the regulator to the D

terminal of the generator

- GREEN wire of the regulator to the F

terminal of the generator

Your should also insert a fuse before the

ammeter. I use 15 Amp. If your battery if heavily

discharged when you first commission the system you may blow the

fuse if you turn the headlight on. Actually it is an

inexpensive and meaningful test that I have run

accidentally. Assuming I built the generator (or at least

it was wired as I would have), to motor the generator:

- temporarily connect the F terminal

to earth

- temporarily connect the D terminal

to +V

The armature should rotate smoothly

clockwise as viewed from the drive end. Doug

Wood 5/14/10

So far there has been three electric starters for Vincents. Both Grosset and Conway starters

operate through the gearbox mainshaft and the primary drive. Both

these are more safely operated with the help of the valve lifter

or a decompressor, particularly if there is a chance of a

kick-back or if you have a very high compression ratio or radical

cams. Bob Dunn's version (also seen on Dick Craven's Prince)

drives the crankshaft directly and appears to be immune to such

phenomena. But its not as pretty. I always use

the valve lifter (Conway starter) but there have been occasions

when I forgot. That's ok with a warm engine but otherwise the load

will hammer any battery (up to 16Ah) into low voltage at which

point the starter solenoid tends to drop out. Eddie

3/7/10

Altette Horn

Manual: http://www.britishonly.com/pdf/lucas/sectionL7partA.pdf

10/3/09 http://www.bolsover.com/lucas/sectionL7partA.pdf

8/21/10

To test

your Miller D6 first

determine which of the four wires are the field coil and which

are the resistor. To do so measure the resistance between

all pairs. If you measure two wires not connected, i.e.

one from the resistor and one from the field coil you will

measure a very high resistance. The resistance coil will measure

two to three time higher than the field coil. The

resistance coil can be ignored for the moment. Pair a field coil

wire with a brush. Don't stress over which wire or which

brush. Pair the remaining field wire with the other

brush. Connect the two pair to a battery. It does

not take much thought to realize that the armature, the field

coil and the battery are now all in parallel. The generator

should now motor. It should motor smoothly. If it

does not motor smoothly something is wrong and should be

addressed.

If the armature rotates CW as viewed from

the drive end then you guessed correctly. If not swap the

field wires and try again. Now take you volt meter and connect

it in place of your battery. Drive the armature CW and

your generator should create a voltage. If not something

is wrong and needs to be addressed.

If the generator passed all tests is

basically works and you can consider wiring it as a Lucas or as

a Miller. Doug Wood 5/29/09

Miller dynamos, as originally wired, work differently then

Lucas. Millers have three states of operation:

1. Output voltage is too low

2. Output voltage is about correct

3. Output voltage is excessively high.

In the first state the armature voltage is

impressed directly across the field coil. Assuming that

the cut-out relay is closed this would also put the battery

across the field coil. If the voltage is low enough then

the battery will be disconnected (as in start up

conditions). This will maximize the current flowing

through the field coil, implying a maximized magnetic field.

In the second state, where the system has

equilibrated (sort of), the current through the field coil is

decreased but not to zero. There is a resistor that is

inserted in the field coil circuit. The resistor, which is

the second winding on the field coil (wound non-inductively) is

the mechanism for decreasing the field coil current.

The third state has no current flowing

through the field coil. Without this current there can be

little or no output voltage.

While this system sounds good, in practice

it barely works. It is a fragile design that typically has

been abandoned for the simplier Lucas type voltage control

(states 1 and 3 only). I am not aware of any solid state

regulators that will support the Miller regulation design,

This is not to say that they could be designed but rather that

there would be little demand for them. Based on that

assessment I would hazard a guess that your 30 year design would

require rewiring the Miller.

FWIW I will not rebuild a dynamo in the

Miller configuration as I do not trust the reliability of the

regulation system.

Doug Wood 5/28/09

Even if properly polarized,

if you're not providing 6V/12V

power to field coils when

testing ouput on the bench .... or a lathe, then output is very

negligible, like less than a volt at lower rpm. To put

it in perspective, most mechanical regulators excite (switching on

power to the field coils to begin charging) at only .50 volts -

and a POD at .75 volt - generator output as the generator is

only using residual magnetism within the field coils at that point

to produce anything. Peter 5/27/09

Alton 2 phase 12

volt battery: Yuasa BZ14. 14 amp hour 12

volt battery, as recommended by Francois Grosset for his electric

starter. It fits the standard carrier without modification.

Old Lucas Booklet:

All about Dynamos: http://www.motos-anglaises.com/catalogues/magazine/motor-cycle/dynamos.pdf

Bruce Metcalf

Gel Battery:

This one costs a bit more but it fits very nicely and puts out 14

Amp hours which is unusually high for a small 6 V . Size is 2

3/4 x 4 3/16 x 5 1/2. Called the dealers and the price was

$29 2 years ago.

http://www.parmakusa.com/Additional/parts.htm Mike Hebb

4/12/09

Gel Battery:

http://www.voltmanbatteries.com/servlet/the-53/SLA0975%2C%C2%A06-VOLT-14-AMP/Detail#itemadded

6volt,

14

amp.

Check

the

dimensions. Mike Hebb 12/12/09

WESTCO 6 Volt Gel Battery

see:

http://www.westcobattery.com/battery_page.php?bid=59&vid=-1

6.5'' and 7.0'' HELLA headlamp complete w/ a parking bulb that Fits our Miller headlamp shells. All @

$19.00

Store Name: PUMA Store

Address:1670 Enterprise Pkwy.Unit E

Twinsburg ,Ohio 44087 USA

Phone: (800) 354-

3552

330-425-2800

Fax: 330-425-2818

Email:info@puma-access.com

http://www.puma-access.com/index.php?main_page=product_info&cPath=9&products_id=287&zenid=85370e6e350b5ffe572ff792b5d725c2

General sources of 6 and 12volt Halogen

headlight bulbs:

http://www.startright.co.uk/index.php?main_page=product_info&cPath=145_285_286&products_id=8662&zenid=4edbbd43957c80bbd25d3f9c04e551f4

http://www.nextag.com/h4-halogen-bulb-6-volt/products-html

http://store.candlepower.com/bconah4ha60b.html

http://www.flandersco.com/action.lasso?-search&-database=_Flan_Levers.fp5&-layout=Electrical&-Format=ElectricalResults.html&-Error=ElectricalError.html&-Operator=Contains&Electrical%20Photo%20Prefix=G

http://www.bikebandit.com/product/A4557898

http://www.yamaha-xt500.com/newshop/index.php?productID=101

Also, JC Whitney has them in 55/60W. Part

number is ZX304576F.

Carl and John 12/1/08

Hella headlight unit: Q. Are these "right hand dip" US

style, or do they, er, swing both ways the way Cibie units

did? A. For UK applications use the repro unit

designed for the Honda CB250N Superdream. It drops straight in and

takes the H4 P43T standard bulbs. Neil Diggins 12/1/08

6 Volt sealed

battery:

http://www.westcobattery.com/battery_page.php?bid=59&vid=-1

Headlight: I used a Honda V45, 1982-83 headlight

#33120-MF5-751. It comes as a unit. You break the glass chisel out

the caulking and re-install the unit into your Miller shell. It

accepts a 65W quartz halogen bulb. With the Miller lense in

place you can't tell what kind of reflector is used. Franc

Trento at franc@eurobrit.com.au is reproducing precise replicas of

the Miller lense. Carl Hungness 9/4/07

Headlight: I am pretty sure that a HELA #70003 light unit

will fit a 6.5 inch rim. John Mead 9/4/07

Bosch GL9 Points =

1951-57 Reliant Bosch GL98 Condenser =1953

P24 Plymouth- Sunbeam-Vauxhall Velox

These are the correct points and condenser for

the Vincent Distributor (DKX2A). They are readily available in any Auto

shop in Australia. Greg 6/18/07

Dynamo Checking:

Let us assume that you want negative earth as Vincents (certainly

with a 3-1/2" dynamo) should have. Also I will assume that the

dynamo is off the bike. If you position the dynamo so the

commutator end is toward you and the armature at the 12:00 position

the brush on the left side should be the ground brush and the brush

on the right the positive. Additionally there are two field

coil wires coming from the bowels of the dynamo, one of which may or

may not have an ientifying tag. Small matter. Temporarily

connect one field coil wire (doesn't matter which one) to the ground

brush and the other to the positive brush. Now connect the

battery to the dynamo, actually now a motor, one battery terminal to

each brush, negative to the earth brush.

If the armature rotates clockwise viewed from the drive end we

have the field coil hooked up correctly. Otherwise reverse

the field coil wires and repeat. It is necessary to get the

dynamo to motor in the correct direction to ensure the field pole

shoe is properly polarized.

Now comes the time to connect the regulator. In general

there are two types of which I know: high side switching and low

side switching. What does that mean?

The dynamo output voltage is limited by switching field coil on

and off. Output voltage too high? Disconect the field

coil. Output voltage too low? Reconnect the

field coil. Only one side of the coil is disconnected.

PODtronics and (I believe) Bell regulators switch the low

(negative) side of the field coil. This is true irrespective

of positive or negative earth. I cannot say with certainy

anything about the switching of the JG or K-Tec units.

There are at least two 4BA screws coming through the brush

plate. One of them may be common to the positive brush

(it is when I rebuild a Miller). It is worth checking with

your Ohm meter. The other is probably just a tie point for a

field coil wire. Check for (lack of) continuity to

everything. Doug Wood 6/1/07

Relays & Switches: It’s

surprising how much you can get into the headlight shell. In mine,

I’ve got a couple of automotive-type relays each wrapped in

rolled-up strip of foam rubber so that they end up 1-5/8” dia. x

2-7/8” long. The fit in to either side of the ammeter.

One of mine is a latching relay (e.g.

http://www.autoelectricsupplies.co.uk/product/178 ), and the relays

are rigged up so that only a single thin wire goes to a simple

push-button switch on the handlebars. When the headlamp’s switched

off, the push-button acts as a flasher (using both headlamp

filaments), and when the headlamp’s switched on, the headlamp

toggles between main and dip with each press of the pushbutton. My

ammeter has a white plastic translucent case, and as a main beam

tell-tale, I’ve got a couple of LEDs mounted on a tiny piece of

Veroboard on the ammeter fixing studs so that the ammeter glows

green when on dip, and blue when on main beam (and also of course so

I can see the ammeter reading in the dark). I’m

running a 6V Altette horn on 12V, so I’m not worried about voltage

drops in the horn wiring, and I don’t keep my finger for ages on the

horn button, so I use a similar thin wire between the headlamp shell

and horn button.

I’ve made a replacement for the throttle twistgrip body with a

homemade switch built into it for the horn. On the left-hand side,

I’ve got a symmetrical lump of stainless which (i) acts as the

clip for the valve lifter main bracket and (ii) houses the

dip/flasher switch. The two thin wires run in a length of

heatshrink from the headlamp shell to the underside of the

handlebars between the handlebar mounting clips, where they go

through a little hole and then run in opposite directions inside

the handlebars and come out through little holes next to my lumps

of stainless. All in all, it results in very uncluttered

handlebars, with the clutch and valve-lifter levers and the horn

and dip/flasher switches nicely placed.

The other nice feature is that the stop has broken in the Miller

light switch, which fortuitously provides an extra position in

which only the pilot bulb is on, so that can be used as a daytime

running light without wasting precious Millertricity on the tail

and speedo bulbs. I think I’ve got one of Goffy’s

(NORBSA02@aol.com) 23 W halogen bulbs

(http://www.norbsa02.freeuk.com/goffybulbs.htm) in there as the

pilot bulb. Ken 5/26/07

Wiring Harness: Boating

suppliers

like

West

Marine

carry

wire, sometimes referred to as "boat cable" or "boat wire". that is

much superior to the bare copper sold in auto parts stores. It has

finer, tinned strands, so it is more flexible and corrosion

resistant than the auto store stuff, and easier to

solder. Steve Lindbloom 5/25/07

Battery Ground:

This all imprtant connection is relegated usually to the common thin

wire held against the side of the oil tank, usually a high

resistance affair. Use a heavier wire with a

suitable eyelet bolted to one of the studs holding left side

plate FT 5 . If an electric starter is fitted this

grounding becomes even more critical. On the

Vincati we use a heavy ground cable from the battery post

sourced from a big Jap bike - the size of your

little finger. All ground wires possible connect

to a heavy common cable and also bolt to this

plate. All lights are brillant and the Alton

worked powerfully from day one. The battery stays

up beautifully too. We run twin in line

fuses - one for the general system, another for the starter 's

solenoid circuit. A key switch shuts off All

power after it passes through the fuse, then supplies these two

systems. Thus there is no drain nor hot wires with the keyed

switch { beyond the switch } turned

off. Sid 5/25/07

Modern Lights:

A

good

headlight

replacement

is

the HELLA unit. The glass cut is very good for driving, directing

the light where it needs to go. The glass sticks out from the rim

about a 1/16''. There are two sizes and not to worry about the ''T''

clip 6 1/2'' headlight shell/ rim, one of these two will fit.

contact: PUMA or Preformance

Unlimited

30700 Bainbridge Rd

Unit L

Solon

Ohio

44139

Telephone 440 498 0638. Fax. 440498 9647 (new address/phone

1/19/02)

The ''T'' Clip headlight unit takes #70003, or

hella #1A6 003 402 812 12V unit 154 The cost is about

$33.00 +/- bucks.

The 7'' split rim headlight takes # 70476 @ about $ 42.00+/-

bucks

Run a modern quartz-halogen headlight bulb an H4 of

amy voltage, any wattage and the nice thing about these are, they

have a parking bulb (nobody I know leaves a light on when

parking), already built in. For those states or

countries that require a 'lights on' driving situation, don't

touch the actual glass of the bulb. JS Wilson 9/26/01

Lucas Generator Parts Misc:

Generator - Lucas 20013

Armature - 200304, E3HM-LO 1946-47

Commutator end bracket - 200270 or 200269

Drive end bracket - 200353

Field coil - 200188

Through fixing bolts - 200227

Band cover - 200609

Brush set - 200290

Brush spring set - 200079

Brush gear (insulating plate) - 200431

Commutator end cover - 200354

Shaft nut - 170104

Bearing bush, Commutator end - 200231

Drive end bearing - 189307

Sundry parts kit - 249683

Jim Baltusnik 7/4/06

Lucas Distributor Parts Misc:

Series "D" Vincent - DKX2A

Bearing bush - 420406

Distributor base - 400001

Rotor arm - 400052 (not sure of this number)

Condenser - 400136

Shaft and action plate -

Coil - model LA-6 volt ignition coil, Part No.

45076

Contact breaker -

Distributor cam -

Clip cover retaining - 410591 or 420261

Lucas Magneto Parts Misc: (for "C" Shadow

and Rapide): (for extensive

Magneto information please see the Magneto Tech Section)

KVF GM1 42134

Contact Breaker Cover: 458647

Contact Set: 470877

Contact Breaker End Plate: 458633

Armature: 458679

Cam Ring: 458661

Contact Breaker Springs: 470688

Spring and Pin in CB COver: 458613

Slip Ring: 454497

Auto Advance: 47505

My '54 Rapide has what I

think is the usual four-position Miller

switch marked:

"Off",

"Ch" (which is still off),

"H" (head, tail and speedo)

and

"L" (pilot, tail and

speedo).

If you are unfortunate enough to break off the

bakelite stop inside the switch, you'll find you aren't so

unfortunate after all. You get a fifth position, and then a repeat

of the same five positions with the other end of the knob pointing

at the markings. The extra (unmarked) position gives you pilot

only, without speedo and tail, which is great for daytime running

especially with a bright little halogen bulb for the pilot.

If you want to go a stage further, you can swap the dipswitch and

pilot light connections to the switch. The "H" and "L" markings on

the switch are then the wrong way round, but the fifth position

then gives you head, again without tail and speedo. Ken

Targett 7/16/06

Battery: All other batteries I've run into sort of fit and

put out 6 to 10 Amp-hours. This one fits very nicely and

puts out 14 Amp hours. Size is 2 3/4 x 4 3/16 x 5 1/2.

Called the dealers and the price was $29. See

http://www.parmakusa.com/Additional/parts.htm if

intersted. Mike Hebb 6/18/06

Headlight

wiring: when fastening

wires to the Lucas brass connectors in the headlight switch or

horn..... always hold the connector with a small open end wrench

against the tourque of your screwdriver.... this will prevent the

connector from tearing loose by breaking the plastic or compressed

insulation material used on the horn.(You have disconnected the

battery- haven't you?) Rip Tragle 4/26/06

Marchal headlight

bulbs for Miller 6 1/2" Vincent Headlights: I

stock 6V 35/35W Quartz halogen Marchal headlight bulbs. These

are a direct replacement for the original and a lot brighter.

They are £12.00 ea. ($21.00). I also stock 6V 10W & 20W

quartz halogen pilot bulbs in both 9MM ad 15MM bases. these

are ideal for a daytime riding light. £4.00 ea ($7.00) Post to

US 2/3 days £2.00 ($3.50) Visit my website

www.norbsa02.freeuk.com Paul Goff 3/26/06

Headlights: A fine replacement for the stock Vincent reflector

can be had by obtaining a 1982-83 V-45 Honda reflector. It fits

into the Miller 7" assembly perfectly and of course accepts the

quartz halogen bulb assemblies. Carl Hungness 3/23/06

Kubota alternator (15531 64010) and regulator

(19267 64602) can be adapted for Vincents.

McDouglator

Technical Article by Carl Hungness

RB 107 Lucas Regulator info:

http://www.britishonly.com/pdf/lucas/sectionL3partB.pdf

Vincent headlights were in three configurations to the States. Early

had the 8". Later came with the 6 1/2" which utilized a

bulb. Also common in the States (and France) was the sealed

beam headlight. (Lucas 400

series 7 inch) These had

a different rim that was split at the bottom. It also had a

locating notch at the 11 o'clock position for the sealed beam

unit. These are really two different components. The most

distinctive thing about the Miller headlight utilized (by Vincent)

was the triangulated boss on each side where the bolts screw in. I

don't think that Vincent used the 7" version which has no boss but

then I'm not sure. I don't think that Phil Vincent would

come running into the assembly line shouting " Shut down the

production line, Miller can't supply the proper 61/2 units

and we can't have concours judges arguing 50 years from

now." Velocettes also used them as well as the 7" units. To

confuse things more, when Harpers took over both, if you ordered a

headlight, they would send a 7" unit with a Vincent wiring

harness. Not that any of this mattered, they were all connected to

Miller generators. Somer 1/1/05

A Vincent does not have a 7 inch headlamp

Shell- that is Velocette. Vincent headlamp is 6.5 inch

nominally. (The lamp does not vary in size [but nothing

surprises] however 7 " lenses Were sometimes fitted with a

big rim for the USA market. With a tape measure, measure the

arcate (accurate ?) length of the bit that sticks through

the rim ...6.5 inches or it's just under 6.5 inches at the widest

point.. with a ruler. OK replicas of the 6.5 inch unit are now

available from a Velocette guy (ironically) in UK who makes them

in India. The glass is not right but OK. Arthur

1/1/05

Podtronics manufacturers two entirely

different types of voltage

regulators.

#1 For AC alternators. Turns AC into regulated DC.

Creates heat in the process. This is a rectifier-regulator.

#2. For DC generators. This is a true regulator and controls

output by modulating the field current. They generate a

small amount of heat as a by product.

The above mentioned #1 regulator is intended for AC alternators

such as used on late BSA, Norton & Triumph. Also used

on Alton, which is an AC alternator. This

regulator-rectifier turns the AC into regulated DC, and turns

excess electrical energy into heat. Do NOT cut off

fins. Do NOT mount in enclosed space. Do NOT mount in

Miller box.

#2 The second Podtronics regulator is a DC regulator

intended to be used on DC generators (dynamos) such as those used

on 50's (and earlier) BSA, Norton, Triumph, and Vincent using

either Miller or Lucas generators. These are very efficient and

yes, they CAN be mounted inside of the old mechanical Lucas and

Miller regulators. There is a small amount of heat generated

as a by product, but is of no consequence. (All components

inside this regulator are certified up to 125 degrees C.) We

have done bench testing using a fibreglas replia Miller box with

no problems after an hour of running time.

Bob Kizer 12/11/03

Great list of sources for Generator and

Magneto repair:

http://www.1bigred.com/blancard/Resources.html

jim 11/11/03

Ignition Advance: Blued pipes occur as a result of idling and

running with the ignnition firing point being held too long

too near TDC. The result is burning being sustained too far

down the power stroke, actually a plume of flame extends out the

exhaust port and down the pipe for about 8 inches - more or

less. In fact mixture correctness can be judged by the

flame's color. Extreme top end heat and oil

temperature results as the cooling fins are unable to dissapate

the added heat. Sid Biberman 7/8/03

Waking up a

Generator: In order for the generator to start

spontaneously there needs to be some residual magnetism in the field

coil shoe or less likely the generator body itself. The shoe

is made of (I believe) soft iron and as such has fairly low magnetic

retentivity. So you have to "flash" your field on occassion.

Flashing the field forces a curent to flow through the field winding

creating the attendant magnetic. The domains in the field shoe

align and remain so when the field is removed. This is

the afore mentioned residual magnetic field.

How to flash your field? Assuming you have a negative earth

system and a Bell regulator, try temporarily connecting your

armature output (possibly labeled "D" or if color coded a yellow

wire) to the + terminal of your battery. This will bypass

the "cutout" diode in your regulator. Then momentarily (<

one second) connect your field output (labeled "F" or perhaps a

green wire) to ground. Your field is now flashed.

Disconnect all temperary connections and reconnect permanent

connections. Doug Wood 4/21/03

Headlight bulbs: The six volt is a "Stanley" brand, # A6867 .

6V30/24W. You should be able to order a box of 10 from a good Auto

parts source. The side lamp is a 6V bayonet base flash light (four

cell) bulb. If you think the bike will be used in the dark, I'd

highly recommend that you contact Bill Easter for a Quartz lamp

conversion. John 6/24/02

Armature Failure: If you have positive charge when lights are not

on, then it sounds as if your headlight is drawing an excessive

amount of current.

1. Try installing a standard 25/35 watt

headlight bulb (25 watt low beam) and see if that makes a

difference.

2. Check to make sure that both high and

low beam filaments are not on at the same time. This will

put a tremendous load on the dynamo.

3. Make sure you have a seperate ground

wire running from battery chassis earth to headlight earth.

Bob Kizer 4/21/02

Armature Failure:

In all my years of refurbishing dynamos, the usual cause for shorted

turns, open turns, or shorts to the core is because the owner

expected too much of a device which was made cheap. Often the

regulator was set too high so that the overall charging rate

exceeded 10 amperes plus the two amperes required for the field

winding, thus causing the windings to overheat or the solder to get

thrown out of the commutator. Rewound armatures with modern

insulation and being dynamically balanced can go a long way toward

improving reliability. Perrry Gerhart 4/21/02

Battery Technical

Site: http://www.largiader.com/articles/battery.html ( updated 8/30/10 )

Amateur's Guide to Horn

Restoration: I've stripped and

repaired several horns and there's not much to them. They contains

a coil, and set of points and a diaphragm. The points are in

series with the coil and when they open, the coil's magnetic field

collapses. They are so positioned that when current enters the

horn the coil pulls the diaphragm inwards and opens the

points which collapses the field which releases the

diaphragm which closes the points and gives us magnetism

again and again and again... .

My steps are:

1. Disassemble - You shouldn't have to open

the big nut in the middle of the Diaphragm but open everything

else.

2. Clean any spider nests and rust out of

the inside.

3. Check the current path for opens or

shorts.

4. Clean the points and all screwed

connectors to bare metal.

5. Clean and oil all threads.

6. Check coil for continuity. If it is bad,

give up and get it rewound or find another horn. If

you don't have a meter, briefly apply voltage through the coil

and see if you get magnetism.

7. Make sure the adjusting screw on the back

really does change the point gap when turned and the spring

works.

8. Reassemble and test. Use adjuster on the

back to adjust the horn tone and volume. If it makes just one

pop of the diaphragm when you try it, the points are not opening

when the diaphragm pulls in. If it makes no noise, then the

points are open when current is initially applied and they

should start out closed.

9. When you get some noise, turn the

adjusting screw till the sound stops in both directions and pick

the best tone in between.

Be especially careful where wires attach to

the back. If they are open and can get wet, it can short from

the connection to the horn body and cook all your wiring. On the

Vincent the horn wire is always hot and it's activated by

providing a ground path with the switch. An inline fuse is

advisable.

10. Polish, paint, rechrome or whatever you

like to the outside and you're in business.

Mike Hebb 3/9/02

Vincent Twin Electric

Starter: (Note: a complete set of Vincent installation

instructions is available

here.)

Four different designs of slip clutch and

electric motor were tested during the development of the Vincent

electric starter. The Mark IV version has been selected after a

test period of 1000 starts which consisted of 50 starts per day

for three weeks.

An 1100 Watt starter motor,located under the

gearbox,is mounted on a special “G50” alloy pivot plate and is

quite inconspicuous. The power is transmitted to the gearbox

mainshaft via a reduction gear (400 RPM at crankshaft). A

specially designed slip clutch is used to disconnect the starter

motor when the engine is fired. The original kickstarter remains

operational;

G46 rachet pinion needs an easy modification

with a lathe. A 12 volt 12 amp/hour jelly battery fits into the

original battery carrier.(Yuasa YTX 14BS), only a longer anchor

stud and modified clamp strap are needed. The extra weight

to the machine is approximately three kilos.

No alteration to the crankcase is

necessary. A slot must be machined into the kickstart cover.

This modification is reversible. Should you wish to return to

the original design, weld a piece of alloy to fill in the

machined slot. The conversion is delivered as a kit including

all the necessary parts exept the battery which is available

from any modern bike shop.The kickstart cover and rachet pinion

may be sent to the address below and will be returned ‘ready to

fit’ with all the parts.The assembly can be done by any good

Vincent enthusiast mechanic in a standard workshop.

Price : 1400 Euros the

complete kit with a second hand checked starter motor,

available

for

positive

earthed

machine

only.

1500

Euros

the

same

complete

kit with a brand new starter motor,

available

for

any

positive

or

negative earthed machine.

Prices

do

not

include

postage

or shipping charges.

Contact: Francois Grosset, Le Pont Ricoul,

35720 St Pierre de Plesguen, France.

FAX: 33-299-73-94

17

E-mail: pontricoul@aol.com

KVF Vincent Magneto Trivia

KVF dated 3/46 P403K, C225

On one side of the mag body, up by the flange, is cast P403K.

180 degrees out, on the other side of the magneto is *stamped*

LT7277

Stamped coaxial with the armature, mid body, left side viewed

from drive end.

H84 stamped coaxial with armature, mid body, top.

Both mags have the letter U stamped on the

bottom, close to the

mounting flange.

KVF dated 1/51 P403K, H84

KVF dated 3/48 P403K

KVF dated 12/51 P403K cast in circular logo

1/2"dia. jim

Modern Lights: A good headlight replacement is the HELLA

unit. The glass cut is very good for driving, directing the light

where it needs to go. The glass sticks out from the rim about a

1/16''. There are two sizes and not to worry about the ''T'' clip

6 1/2'' headlight shell/ rim, one of these two will fit.

contact: PUMA

or Preformance Unlimited

30700 Bainbridge Rd

Unit L

Solon

Ohio

44139

Telephone 440 498 0638. Fax. 440498

9647 (new address/phone 1/19/02)

The ''T'' Clip headlight unit takes

#70003, or hella #1A6 003 402 812 12V

unit 154 The cost is about $33.00 +/- bucks.

The 7'' split rim headlight takes #

70476 @ about $ 42.00+/- bucks

Run a modern quartz-halogen headlight

bulb an H4 of amy voltage, any wattage and the nice thing

about these are, they have a parking bulb (nobody I know leaves

a light on when parking), already built in.

For those states or countries that require a 'lights on' driving

situation, don't touch the actual glass of the bulb. JS

Wilson 9/26/01

Testing your Armature: One side of the condensor should be

unsoldered. I would recommend the side opposite the HT

turret on the slip ring. Primary (low tension) resistance as

measured from the amrature core to the wires that you just

unsoldered shuld be approximately 0.5 Ohms. Secondary (high

tension) resistance measured from armature core to slip ring brass

should be 5000 - 5500 Ohms. Doug Wood 06/24/01

Polarity: With everything connected up just depress the

cutout contact for a few seconds. This will direct charge

from the battery around the field windings and re-magnetise the

field magnets with the correct polarity.

Battery: Walridge Mtrs list a 6 volt black rubber original

style ( p.94/2000 cat. p/n 14075 2 $105.82 cdn). Also listed

is black rubber shell with lid similar to original 6volt battery

(p/n 99-920 $47.96 cdn). They also state they can supply 6

or 12v battery to fit inside case, no price or p/n given. They can

be reached at E-mail: walridge@gtn.net or Phone: 519 641

2770 or FAX: 519 473

3960 John Cousens 05/06/01

I thought that I would put

the facts on the table as to the

development of the Alton.

This started back in , I think 1989, when I

was seen by Herve Hamon with a Kubota alternator in my hand at

an Annual Rally ( Fort Purbrook, Portsmouth). Herve went home to

France, and having, at that time some paternity leave

French, you know) for a year. A lot of spare time on his hands (

after putting Ettiene in the crib in the workshop, they train

them the right way in France!) Work was then done in

producing some prototypes, using several different methods of

drive ,and speeds. When it was found to be successful, but

lacking in as much that it could only be used on twins, due to

the large diameter of the rotor, it was decided to manufacture

one of three inches diameter, so that it could be used on

all machines that used a Miller or Lucas dynamo.

The initial prototype parts were made by

me, including the tooling for blanking out the segments for the

stator( soft iron) Much time was spent between here

(Hayling Island ) and Auray on the southern coast of Brittany.

Unfortunately One of the early prototypes was seen on a French

bike by a British journalist, and publicity was given , long

before any real development had been carried out. I was flooded

out with enquiries from all over the World. This was something I

did not need, having a business to run , sometimes 50 calls in a

single day, and me not being able to give a sensible answer.

Nowadays most of the parts are made in France, with only some

gears made locally here in Portchester.I do not have any

involvement in the project

now.

This is where I will disagree with the

statement made that the magnetic pulsation's of the Kubota, are

the cause of taking out the rollers on the primary chain. If a

Kubota is held in the hand and given a quick twist of the wrist

it will spin easily, until it slows down enough for the magnets

to take over again . So when the alternator is running this

effect makes no impression . What does happen is that there is a

far greater load, than what was developed by the original

dynamo. Bikes that have a Fiat or Bosch automobile dynamo have

also been known to shed their rollers. It`s the increased

load that is the problem. That and poorly maintained chains ,

running far too slack. Getting the sprocket in the right

place , central to the links , and with a good clearance above

the rollers, helps. A plastic sprocket is being

experimented with to see if it is a going concern.

Trevor 04/30/01

The rearlight wiring runs up one leg and the stop light wiring up the

other. Also if you look under the rear hinge, you will find

grooves milled out for the wire to pass under this component and

then onto the rear/stop light assembly. D.J.P. 04/27/01

Do-it-yourself magneto: The ordinary multimeter applies only a few volts

across the terminals.

Use a megohmmeter with 500 volts

applied. 1000 megohms is a reasonable value. The

capacitor needs to be disconnected from the coil. Test hot

at 180F. Test the coil for leakage, same way. Test

the isolated coil for passive voltage with the 200 millivolt

scale on an ordinary multimeter. The higher the voltage(5

to 50 millivolts) the more water is is the coil. Bake

it out for day or two at 180F( post

bake voltage should be less than 10 microvolts) and recoat with

coil varnish.

Encourage Doug Wood and Bob Kizer to write

a manual for these tests, defects, and cures. Perry

Gerhart 03/31/01

<<Did you use a megaohm

meter on the mag to verify that the condenser is working as it

should? This is the only way

to accurately check a mag condenser.>>

Yes, a megaohn meter will act as a

capacitor tester as it will judge the ability to take on and

hold a charge. (as does a capacitor tester) I"ve tested hundreds

of Lucas capacitors and haven't found a "good" one yet.

They are all leaky to one degree or another. Even if you

find an NOS one still in the box, it will test leaky.

Lucas was ahead of their time in manufacturing biodegradable

parts. (the capacitors used paper dialectric) Bob

Kizer 03/31/01

Along with people, magnetos

and paper dielectric capacitors suffer from old age. A 50 year old magneto

has outlived it's usefulness. To use a "band aid" approach

is to only prolong the inevitable. Overhaul it correctly,

rewind the armature, use a good quality capacitor suitable for

pulse application, and you probably won't have to do it again for

another 50 years.

Bob Kizer 03/31/01

There have been a multitude

of discussions, in print, about how

to time your Vincent over the

years and I have done my level best to research many of

them.

The "poke your spoke"

method of inserting something into the cylinder surely leaves

much to be desired as far as accuracy goes. Moving the engine

5-l0 degrees is actually VERY little.

Once again we refer to

"40 Years On" where methods ranging from dial indicators to

putting a bit of soap over the plug hole (and watching the

bubble rise or fall) to give us Top Dead Center.

No matter how you find

TDC, it is a simple enough circumstance to install a degree

wheel and check yourself. Then simply make up a spark plug stop

(again see the method in 40 years On..whereby you bust up an old

plug, thread a bolt into it, and set it precisely at TDC)

I have utilized my spark

plug stop guage a couple of dozen times to re-time my bike and

am "chuffed like a parrot" to say more often than not she has

started first kick after installing the mag.

Once again, the

installation of the mag, figuring out precisely where the points

open, is covered in the "40 Years On" but to summarize, you take

out the center bolt, hook up a small dash style light, watch it

go on and off..and you 'll know precisely when the points

break.The do break electronically a bit faster than visually...I

know many have used cigarette paper and a "feel" method..which

works well too.

Measuring this spark

plug angle is, yes, like measuring with a mike and cutting with

an axe.I love that analogy..and had forgotten it.

` Remember to block

open the ATD when setting the mag...

I know from experience

this procedure can be done on the road..and I feel confident the

measuring down the hole method has started many a Vin over the

years as well. My point is, make the spark plug stop, carry it

with you and you'll never have to worry about where 38 or 39

degrees is again. Carl

Hungness 03/30/01

Here is a technical tip for

all you Vin/Ariel members that have ammeters with the red jewel in it. I modified Rob Arnott's ammeter by

drilling a .099" hole in the back and gluing a super bright red

LED into the hole with superglue. The LED was connected in

series with a resistor and the resulting illumination was very

impressive with only 20 milliamperes

going through the LED when the ignition was

switched on. Polarity of the LED needs to be observed.

The Vincent had negative ground so I connected one end of the

resistor to the anode, positive, longer lead of the LED, and the

other end to the connection on the ammeter lamp socket with the

white wire on it that goes to the ignition switch. The

shorter lead on

the LED was connected to the ammeter lamp

socket with the yellow wire on it that goes to the dynamo

armature. This can be used for either 6 or 12 volt

systems. I used a 510 ohm, ½ watt resistor for Rob's 12 volt

system. A 240 ohm, ¼ watt or larger resistor can be used on

a 6 volt system. Bill Easter 03/15/01

I had run a Mistral/Lucas

Rita setup for a few years, (once I'd sorted out a

reliable power supply) and it ran very well but,

1) It sucks a lot of power, like almost 4 amps on 12 volts. 2) I

wanted to hide the coils under the Mag cowl and used small twincoils

which would go about 3000 miles and just die. Burn them out, even

expensive Dyna coils, although they did not measure the 3 ohms that

they were stamped with. I didn't want the 2 big old Lucas coi;ls

hanging out in the air so paid the price in coils.

I then switched to HD stuff fitted to the Mistral housing which I

still run. Dan Smith started this, now many local bikes run it,

and John McDougall has been making housings to suit. The benefits

are many. Two stage advance curves operated by a vacuum switch.

Low power draw. Parts available very readily. You can tuck it all

under the mag cowl. There are for those who like to fiddle with

that sort of stuff, programmable boxes that you can program more

stuff than you'll ever need. Do you need to have nitrous

arming and firing points? How about if you have and

electric start you can program the engine to turn over a

designated number of turns before it fires to avoid backfiring on

start up. Robert Watson 03/09/01

Engineer Kirby Rowbotham builds the Boyer Bransden "Micro-Digital" system

into his own replica magneto housing, for mounting in the standard

Vin magneto position, all for £320 (GBP320). These run with

the miniature "digital" coils supplied, to allow two-plugs-per head

firing. I think he advertises in CB, CBG etc. magazines.

His system is claimed to have independent (i.e. per-cylinder)

EEPROM-based adjustability of timing curve. Phil

Blakeney 03/09/01

Does anyone know if you can run a dyno without a battery. I

think you need the battery to excite the field coils to get the

armature to produce current or will this happen when the dyno begins

to spin? John Mead

Hello John, It depends upon what regulator you are

using. If you are using the original Lucas mechanical, there

is no problem.

The voltage to excite the field actually comes from the generator

armature and is switched on and off by the regulator. (this is how

they regulate maximum voltage) If you are using K-tec,

then the answer is no. Because the K-tec uses a Darlington

transistor for field switching, which requires 1.4 volts to

initialize, they use battery voltage to excite the

field. On the other hand, if you are using the

PODtronics DC regulator, there is no problem as it will operate

very nicely without a battery in circuit. (and it fits

inside the mechanical regulator box) Bob Kizer

02/27/01

I have been using a 12V Alton

alternator on my 'C' Shadow for a couple of years

with absolutely no trouble at all. It just always works and I

would recommend one. I find the "break-even" point to run my

quartz headlight, instrument lights, and high wattage running light

to be about 50 mph in top gear--that's fairly low rpm and certainly

the wrong gear for that speed. Its output is claimed to peak

at 150 watts sustantially more than any 6V DC generator.

I tested prototypes for ALTON. My findings were that

electrically it was just fine right from the start and once they

got into production any minor mechanical problems had all

disappeared. It's a nicely built piece of equipment and is a

direct replacement for the original Miller unit except it is 12V.

BTW...I run magneto ignition--no particular reason except it has

never failed me. It does have an advantage if I leave

something on and run the battery dead. Jay Schaffer

02/13/01

A Dynamo is a machine that when driven by a prime

mover, such as a water turbine or a Vincent, is called a

Generator. It changes mechanical

energy to electrical energy. If a Dynamo is supplied electricity and

it's output used

to supply power to mechanical devices it is called a motor.

Generators are rated as to the Watts they can supply at a rated

Voltage and Speed without Overheating. Motors are rated to the

Horsepower they can deliver at a given Speed and Voltage without

Overheating. Now Forget motors! This is about Generators!!

There are several ways to control the Wattage: (One) Speed

Control, that's the thing your right hand does. (Two) voltage

control. That's the thing the regulator does to the field windings

of the Generator. There are two ways that you as a Vincent rider

will deal with hooking up the field to the voltage controller.

(One) in Series with the Armature; (Two) in parallel, or

Shunting, The Armature. You can hookup any Miller, Lucas, Bosch or

Chinamo to do either. JG units are hooked series, or externally

grounded, K-Tec, Lucas regulators are hooked Parallel or,

internally grounded. By looking at the drawings in KTB,

Richardson, diagrams that were supplied with your regulator or, by

looking in an old Auto repair manual you'll be able to see these

differences. Since all these Generators were made to run in

motorcycles you can see the speed part of their rating can be

anywhere from less than two thousand to over seven thousand RPM!

If they are not overheating they are safe, so go ahead and spin

the generator a little faster, it won't bother it a bit. One

Hundred-Twenty watts at twelve volts is still in the working range

of Your Sixty watt, Six volt Generator. John 12/20/00

Looking at the diagram by JG, it appears that the

gen is wired in shunt. I believe that the JG unit varies the

current through the field to regulate the output. It is a

parallel generator. John 12/20/00

Dynamo: I fitted a good condition E3L generator, only

modified in the wiring as explained by JG, and a 12 volt JG

regulator to my "D" Comet some years ago. The instructions with

the regulator said that it would produce 12 volts with

approximately double the output. This is what it has done

without any troubles, until I removed it about two months ago.

However, a later modification on this side

of the pond is to fit the distributor from a car and have 12

volts with an out put of 15amps or more. One of the favourites

is the generator from a Citroen 2CV, due to it's small

size. As I have plans to update my lighting and possibly

fit an electric starter, I have fitted a car generator to

the Comet. Of course there is much more room to fit it on

the Comet, so I have fitted a slightly larger generator that has

the rectifier pack and the regulator mounted under

the end cap. This is driven from a

small dummy dynamo incorporating a pulley at the non-drive end

which in turn drives the alternator with a poli-V belt.

The finished results have been very impressive, with the

alternator balancing the load of every item on the bike at a

fast tick-over. Derek Peters 12/20/00

When Joseph Lucas designed

the dc dynamo, he did so with neither an excess of steel nor

copper. Of course, it depends upon what size wire is used in

the 12v rewinding. When going to 12 volts, less current will

be required to do the same amount of work. In order to get

higher voltage (at lower rpm) the wire must be smaller so

that more wire can be wound on the armature. And of course,

smaller wire has more resistance, thus increasing the I^2*R

(current squared times resistance). So yes, all things being

equal, you still have a 60 watt instrument. However,

by using a 6-to-12 volt conversion regulator, you can use that 60

watt headlight whilst utilizing that 6 volt armature. The

only "problem" is that you must spin it faster to get that full

12v output.

If you use a JG converter or similar you

can use a 60/55 watt headlight bulb bulb. The converter will (or

should) protect your delicate little field coil from harm by

limiting its current. At 12 volts, the field coil might

draw as much as 6 amps. Bob Kizer 12/14/00

Both a generator and an alternator do the same thing: convert mechanical energy

(rotation) and magnetic energy (either a permanent magnet or a

field winding) to electrical energy. As Mr. Kizer so

correctly stated: "There's no such thing as a free lunch."

If you want to get 60 Watts out of a generator you need to put 60

Watts into it...plus energy for all the losses.

If you are simply trying to run a 6 Volt

generator at 12 Volts exercise caution: the field coil will have

the full 12 Volts impressed across it. Since resistive power

increases with the *square* of voltage (all else being equal)

your poor filed coil will be asked to dissipate *four times* the

energy it was designed for. So generally the voltage

across the field coil is limited to 6 Volts. The easiest

way to do so is with a series resistor. But this may not

be the most efficient.

The situation with the armature may not be

so bad. Again, assuming the desire is to run a 6 Volt

generator at 12 Volts the load (lighting, field coil,

accessories, etc) may be specified such that the current

requirements may actually decrease (a primary advantage of

higher Voltage systems). In this case a 6 Volt armature

may work... but at the price of requiring higher RPM.

My take on this situation is:

1. A 45 Watt bulb puts out just about

45 Watts wether it is 6 Volt or 12.

2. All things being equal 12 Volt

systems require less current, therefore are more forgiving of

sub-optimal electrical connections.

3. There is an upper limit on what

you can get out of a 35 Watt generator.

4. There is no upper limit on what

you can put into a 35 Watt generator, short term.

5. It is my opinion that if you want

a 12 Volt system you should convert to 12 volt components (field

coil, armature).

Doug Wood 12/14/00

The generator/dynamo

has two essential parts, the armature and the field coil. These

can be configured in one of two different ways. 1) Armature and

field coil in parallel with each other, and having a common ground

(earth). This is the arrangement as shipped from the Lucas factory

and utilizing the old fashioned Lucas mechanical regulator.

2) Armature and field coil in series

with one brush connection earthed, and the other brush sharing the

"D" terminal with one of the field coil wires. This

arrangement is required for some solid state regulators such as

the JG. Although there are some solid

state regulators that require condition #1.

You can flash the field for one of

two reasons, or both. 1) To reverse the polarity or

2) To restore residual magnetism. In this situation,

we are doing it to increase the residual. Remember, the

mechanical regulators can initialize with as little as 0.1

volt. But due to the characteristic of

silicon solid state devices, they must have in excess of

0.7 volts. This can be accomplished by either

flashing the field, or spinning the armature faster and

faster. The residual magnetism decreases with time.

If the bike hasn't been ridden in several months, it's possible

this will restore the lighting.

The Miller (and Lucas) should have two

outlet termainals. One should be marked "F", and the other

marked "D". The green wire from JG should go to the F

(field). The "D" terminal will most likely have blue or

yellow. I'm betting that flashing the field

will restore operation, but if it doesn't, you might want to

consider the PODtronics. They are designed to be more

efficient and

therefore consume less power, thus

generating less heat. And they're small enough to fit nicely

inside the Miller and Lucas boxes. And yes, the "hot"

terminal is the one that isn't earthed. Bob Kizer

12/14/00

Maybe all open "D's" were fitted with the

Lucas model 564 tail light, but the enclosed models were fitted with model

529. You need to ensure also that you get the right model

529, which is 53429A, as they were also made without a

connection for the Stop lamp. Derek Peters 12/14/00

Regulators: At one time JG was availabe epoxy potted

inside of the owners Miller box lid. It's my understanding

that this feature is no longer available and can only guess it was

because of insufficient heat sinking. (These generate about ten

watts of heat at full output.) Keep in mind that

each time the bike is started, the generator creates output

voltage using the residual magnetism from the last time it ran.

Also, keep in mind the poles of the generator are soft iron and

will not stay magnetized indefinetely. The "drawback" of

solid state regulators is that they require approx. 0.7 volts to

initialize. If most of the field

magnetism is lost, the regulator will not

initialize. But the fix is simple. (please note this applies

only to generators wired according to JG instructions)

1. Disconect the regulator from the

generator (US generator = UK dynamo)

2. Run short jumper wire from "F" to

ground.

3. Attach wire to hot terminal of

battery.

4. Briefly touch other end of this wire

to "D" terminal on generator.

5. You have now "flashed" the field.

6. Disconnect the jumper wires and

reconnect the regulator.

Bob Kizer 12/06/00

While we do have some very knowledgeable and able

craftsmen rebuilding both magnetos

and dynamos who advertise in

the VOC MPH journal, I wish to recommend a couple here stateside

whose names and addresses seem to be fairly secret.

I have had excellent experience with a magneto

rebuilt by Bill Jean 757 488-7l9l of Virginia (Sid Biberman's

partner in the restoration field) and Rip Tragle revamped my

Miller generator to l2 volts and after 20,000 miles seems to be

working great...Tragle is of course a journeyman engine rebuilder

as well..his phone is 9l4 676-3304.

Nevertheless, after some

correspondence with Mark Goodson I am pretty well convinced that

the Chinamo he discovered is well worth looking into..it

generates a very healthy output, and is reasonably priced.

Available from the VOC Spares company. The main problem with the

generating system, my research has shown, is not the generator

itself, but the regulator. And nowadays we have our choices of

several modern ones that seem to handle the load with

consistency

Personally, I love the idea of being able

to start the bike and drive it home, without a battery.

Then again, after doing considerable damage to my knee last

summer I am looking forward to the day I can afford an electric

starter..but I'll still keep the magneto. Carl

Hungness 9/'29/00

How to fit an electronic

ignition unit to a Comet.

I can only refer to suppliers etc. in the U.K. Here most of

the conversions seem to use Boyer Bransden units. Kirby

Rowbottom using a Boyer Bransden unit can convert a standard

magneto to contain the sensor unit, which consists of a magnetic

rotor and a stator plate and then the only other component is a

transistorised control box about the size of a twenty pack of

cigarettes. The only item not included is a standard

coil. Most of them are powered by 12 volts and I would

recommend a conversion. I used a standard Lucas E3L dynamo

and a "JG" voltage conversion unit - this converts the standard

dynamo to 12 volts while doubling the output to 120 watts.

If you have machining facilities I consider the way I did it to be

the best solution. I machined an alloy casing rather like a

distributor and mounted it in the same way as the "D" distributor

so that it can be turned to obtain that final timing

adjustment. This unit had two small bearings, a 1/2 " shaft

and a cavity to contain the rotor and stator. It is driven

by a standard tufnel gear. I dealt directly with Boyer

Bransden, who I found to be most helpful. Initially they

recommended a unit made for the Triumph &BSA

Singles. However, when I mounted it on the bike there was

insufficient advance to allow correct timing for both running and

starting. I phoned their technical department and they asked

me to return the control box. Within a few days back

came a new box bearing the inscription -"HIGH POWER IGNITION UNIT

- SPECIAL: VINCENT COMET - WIDE ADVANCE". Needless to say it

has functioned perfectly ever since.

This advice applies equally to

Twins. Derek Peters

9/29/00

Altette Horn Repair

Issac Lynn "Taff the Horn"

20 the Glebe

Bishopston, Swansea,

West Glamorgan SA3 3JP

South Wales, UK

lynn.isaac@tinyworld.co.uk

Lynn (known as Taff) Isaacs is a ruddy miracle

man on all types of horn. Has 9000 horns and specs on almost every one ever

made. Got me one for my 37 Rudge Ulster, rebuilt my A and the C

(12V conversion). Hardly ever uses pattern stuff (re wiring is

new!!) and charges are embarrassingly modest. (Authur)

7/18/00

Return to:

thevincent.com